LEVACO Chemicals always focusses on innovations and constant improvements - concerning the products as well as the processes themselves. Employees are constantly encouraged to discuss and implement their ideas. Tom Hummel represents an excellent example with his master's thesis in the field of industrial engineering at the University of Economics & Management in Essen, who, as part of the LEVACO Chemicals energy management team, is always looking for improvements in efficiency.

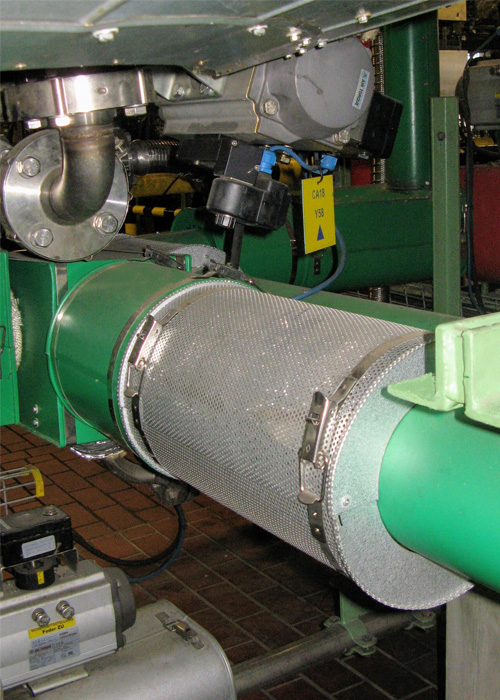

By comparing the conventional float steam traps with the alternative venturi orifice steam traps of EBE Engineering, he found significant differences in efficiency in the use of process steam, which leads to important cost savings.

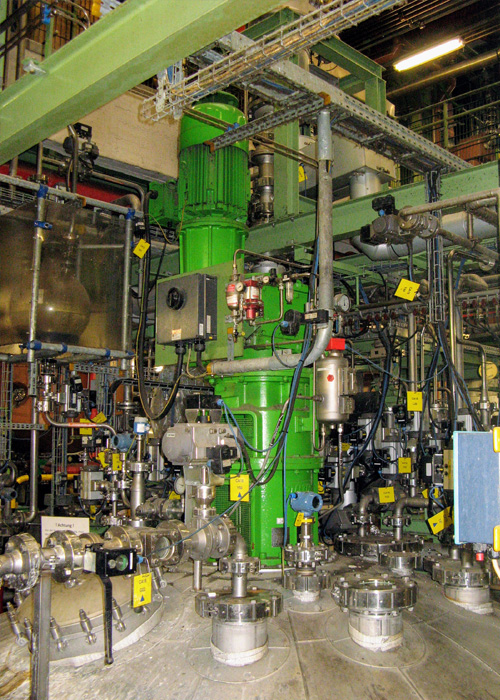

Thus, the venturi orifice steam traps reduce costs through

- significantly lower steam consumption,

- shorter heating times and thus increased productivity and

- due to the same dimensions the exchange of both types of steam traps can be executed without problems which leads to a greater flexibility.

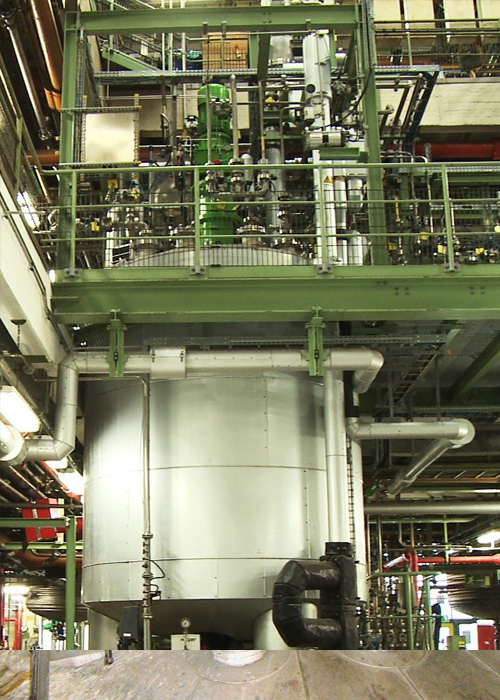

The reactor with a capacity of 20 cubic meters uses approx. 200 tons of steam per year.

Due to their dimensions, venturi orifice steam traps can be easily exchanged.

LEVACO Chemicals manufactures 27 different products with different physical properties in this reactor.

The company is very convinced of the proven benefits. The first steam trap replacement has already been carried out and more will follow.

The magazine PROCESS reports on it in a detailed article.

We thank our employee Tom Hummel for this outstanding innovation in our energy management.